Hoppe Marine GmbH

Booth number: 1D23

www.hoppe-marine.com/

About us

Hoppe Marine is a family owned group with global activities in the shipbuilding market. 75 years’ experience with measuring and control technologies for maritime applications enables the continuous development and improvement of the product range. The integration of the established solutions and brands of FLUME, MAIHAK, INTERING and S-TWO have enriched Hoppe‘s technology and know-how portfolio, which today fully covers the areas of CONTROL SYSTEMS, MEASURING SOLUTIONS and INFORMATION SERVICES

Hoppe Marine solutions are customized, applying an in-house design and a high degree of vertical integration from on-board proven hardware, sensors and actuators. Hoppe Marine fulfils the market‘s demand for smart, integrated systems such as Valve Remote Control, Tank Content Measurement, Roll Stabilization, Dynamic Floating Monitoring, Anti-Heeling / Load Compensation for Heavy Lift Operations, as well as Performance Monitoring, Electronic Inclinometer and vessel digitalization

Address

Kieler Str. 318

22525 Hamburg

Germany

E-mail: sales@hoppe-marine.com

Phone: +49 40 5619490

Internet: www.hoppe-marine.com/

No 485-3, Gu Pyeong-Dong

Sa Ha-Gu

604-866 Busan

South Korea

E-mail: hoppe@korea.com

Phone: +82 514 035851

German Center, Rm. 708, Tower 1, 88 Keyuan Rd.

201 203 Shanghai

China

E-mail: service@hoppe-china.com

Phone: +86 21 50278040

#11-14, Cendex Centre 120 Lower Delta Rd.

69208 Singapore

Singapore

E-mail: service.singapore@hoppe-marine.com

Phone: +65 67 174888

Contact person:

Products & Services

Valve Remote Control- Safe Return to Port VRC-BUS System - Tank Content Measurement - Bunker Safety and Bunker Monitoring – Dynamic Draught and Monitoring - Tank Heating Control and Ice Alarms - Ballast Management - Loading Computer - Water Ingress Detection - Anti-Heeling Systems (pump driven) - Blower Anti-Heeling Systems (options: combination with roll damping, ice heeling) - Stability Test - FLUME Box roll damping system - INTERING U-Tank roll damping – Floating Condition Control – Dock Control - MAIHAK Shaft Power Meter (incl. ShaPoLi-Solution) – Fuel Consumption Measurement - Performance Monitoring - Electronic Inclinometer – MioT Data Collection

SmartShip PowerBus

System Architecture

Dual redundant serial ring bus

Automatic data-rerouting for continuous operability even after bus or Local Processing Unit (LPU) failure

Short circuits also in the PowerBus can be countered while maintaining the operability of the remaining components

Four versatile inputs, configurable as standard 4-20mA or digital inputs to connect any kind of analog or digital input source

Safety concept

Two identical cabinets (master &slave), including all associated input and output modules, operate in parallel and with the same software

A communication between the cabinets monitors all activities of the two cabinets/PLCs

In case of failure of the master cabinet/PLC, the slave cabinet takes over control via Ring Bus

Triple input for the power supply (MSB,ESB and UPS)

Floating Condition Control

This combination of a flow-controlled anti-heeling and ballast system is combined in a central control system with PLCs. A particular advantage of this system is that the necessary operations are fully automated, but at the same time are subject to permanent system control.

Part of this control system is a loading computer to simulate and optimize the ballasting process, the SCADA system and a logging function.

AUTO ADJUSTMENT OF FLOATING CONDITIONS

Simply keep your desired condition - Full focus on cargo operation

The key feature of this system is to adjust the floating condition in the three degrees of freedom heel, trim and Draught automatically over a predefined path.

The system allows a flexible selection of parameters as limitations for the operation, such as bending moment limitations, tank usage, min required GMs or others.

For semi-submersible ships and floating docks this system will fully support the operators to undertake automatic docking operations safely.

AUTO COMPENSTATION OF LOAD TRANSFERS

Faster and safer loading operations

In combination with a main crane, upending gripper, lifting arms, jacking legs or any other relative load & position tracking (Load Moments), the FCC System ensures a constant floating position during any transfer of load.

The load can be transferred along the vessel or from an external position. The application can be a ballast supported jacking operation, an offshore installation job, a load skidding transfer in harbour or other similar tasks you can imagine. Also tidal influence are taken into account at the same time.

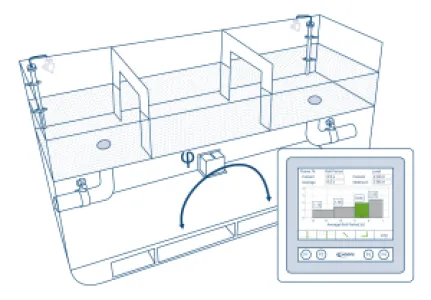

FLUME Box Tank - Anti Rolling

Passive box-shaped roll damping tank

Boosting passenger comfort and cargo safety by reducing roll motions and accelerations

Creating counter moment to the wave excitation

Tank natural period identical to vessel roll period

Adjustment of water level for tank period tuning

Effective at any vessel speed

Reducing vessel resistance