GEA Westfalia Separator Group GmbH

Booth number: 1C33

www.gea.com

About us

GEA is one of the world’s largest systems suppliers for the marine and food, beverage, pharmaceutical and marine sectors, and a leading provider of high-performance equipment for treating fuel oil, lube oil, wash and bilge water, as well as marine refrigeration and freezing technologies that ensure your catch is rapidly frozen and your cargo arrives in optimal condition.

Our portfolio includes machinery and plants, advanced process technology, components and comprehensive services. Used across diverse industries, they enhance the sustainability and efficiency of production processes globally.

GGEA centrifuges and supply systems are engineered to meet both the economic challenges of maritime logistics and the increasingly stringent environmental regulations governing ocean protection. Our compressors and packages, including a broad range of screw compressors, are designed to meet the high demands of marine applications, supporting refrigeration, ammonia, CO₂ and boil off gas (BOG) systems.

We provide complete industrial refrigeration solutions for a variety of marine vessels, including fishing trawlers, refrigerated cargo ships and cruise liners. GEA supports its customers worldwide through a strong global network of service, spare parts and technical expertise.

GEA is listed in the German MDAX and the STOXX® Europe 600 Index and is also included in the DAX 50 ESG and MSCI Global Sustainability Indices.

Address

Werner-Habig-Str. 1

59302 Oelde

Germany

E-mail: info@gea.com

Phone: +49 2522 770

Internet: www.gea.com

6th Fl. Sanhakjaedan Bldg., 329, Gangnam-daero, Seocho-gu

06627 Seoul

South Korea

Phone: +82 2 5140291

Internet: www.gea.com/en/

Contact person:

Products & Services

GEA offers centrifuges for the treatment of fuel oil, lube oil, wash water, and bilge water, along with advanced marine refrigeration and freezing technologies to preserve catch quality and cargo integrity.

Our centrifuges and supply systems are designed to meet the economic demands of maritime logistics and comply with strict environmental regulations. We also provide comprehensive refrigeration solutions for ammonia, CO₂ applications across a range of vessel types – from fishing trawlers to refrigerated cargo ships and cruise liners.

A global service network ensures reliable support, spare parts, and technical expertise wherever our customers operate.

GEA marine Separator

The GEA marine separator specializes in the purification of fuel and lube oil on board ships. With its integrated direct drive, the GEA marine Separator is a revolutionary solution that offers more performance per square meter of space, an extremely simple service concept, and smart connectivity.

GEA biofuel Separator

The GEA biofuel Separator is engineered to efficiently purify marine biofuels, such as HVO and FAME, by removing water and contaminants. Featuring a high-speed, continuous-operation design with an integrated direct drive, it delivers top-tier performance per onboard square meter while minimizing energy use and space. Smart connectivity enables remote monitoring and proactive maintenance. Built from corrosion-resistant materials with easy-access components, it ensures low downtime and long service life. Upgrade kits allow seamless retrofits for older units.

GEA NOx Separator

Specifically designed for Exhaust Gas Recirculation (EGR) systems on marine vessels, the GEA NOx Separator with integrated direct drive ensures reliable treatment of EGR wash water. It removes contaminants such as soot, sulfur compounds, and acidic substances, allowing safe discharge into the sea in compliance with MEPC EGR guidelines.

This separator supports compliance with IMO Tier III NOx emission limits and is compatible with engines running on HFO, low-sulfur fuels, LNG, and methanol. Compact and efficient, it delivers high-performance purification while reducing environmental impact at sea.

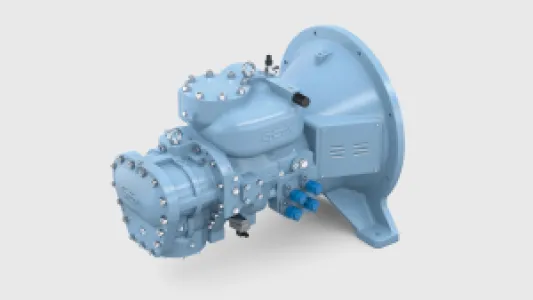

GEA Screw Compressors for Marine Applications

GEA supplies Grasso screw compressors engineered for sustainable, natural refrigerants – ideal for boil-off gas (BOG), low-duty (LD) operation, gaseous ammonia fuel, and CO₂ capture. Each unit is custom designed to meet the specific performance and space requirements onboard.

We are actively advancing gas compression technologies to support future fuel conversions and are already supplying key components for CO₂ capture systems while testing next-generation solutions for the maritime industry